TISL was originally founded with its core services in the field of Non-Destructive Evaluation and to this day it remains part and parcel of our everyday operations but with added technical support from the latest technology and experienced personnel. In recognition of our mission to remain a leader and offer only the best in NDE, we now have three ASNT NDT Level III personnel certified in MT, PT, RT, UT and ET. With these added technical capabilities, you can trust that TISL has the experience and technical background to deal with all the challenges associated with your NDE projects.

- Visual Testing (VT)

- Magnetic Particle Testing (MT)

- Liquid Penetrant Testing (PT)

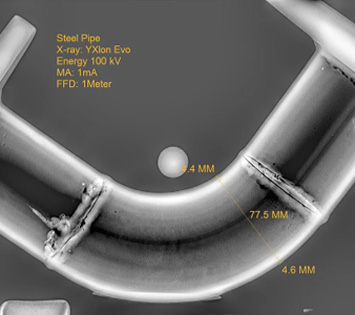

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

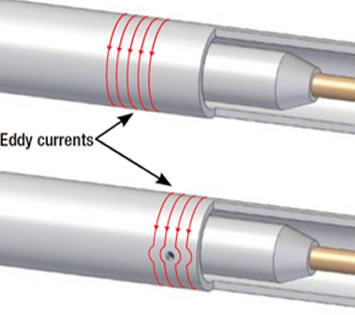

- Eddy Current Testing (ET)

- Magnetic Flux Leakage (MFL)

- Leak Testing (LT)

- Vacuum Box Testing

- Acoustic Emission (AE)

- Airborne Ultrasonic Testing

- Holiday Testing

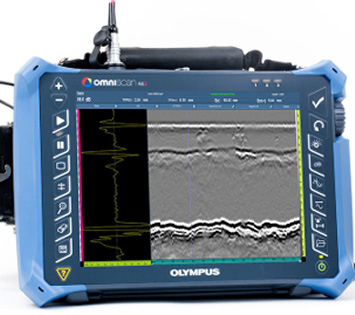

PAUT has become one of our mainstream advanced services that continues to grow as clients become more aware of its benefits over conventional UT. With PAUT, the inspector has the ability to steer, focus and scan beams with a single transducer through the use of multi-element probes individually excited in specific sequences.

PAUT has become one of our mainstream advanced services that continues to grow as clients become more aware of its benefits over conventional UT. With PAUT, the inspector has the ability to steer, focus and scan beams with a single transducer through the use of multi-element probes individually excited in specific sequences. TOFD provides fast inspection of axial and circumferential welds with unsurpassed detection and sizing capabilities. As it is based on the concept of diffraction, it is unaffected by the orientation of flaws or weld bevel angles making it a highly sensitive technique.

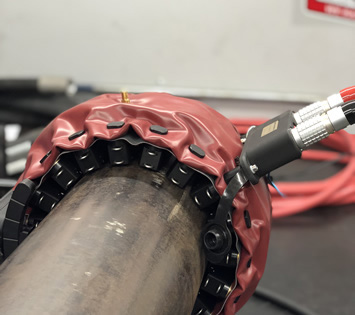

TOFD provides fast inspection of axial and circumferential welds with unsurpassed detection and sizing capabilities. As it is based on the concept of diffraction, it is unaffected by the orientation of flaws or weld bevel angles making it a highly sensitive technique. GWUT is an excellent screening tool for rapid detection of internal and external wall loss on pipe from 4” to over 48” in diameter. It can be deployed quickly and effectively for periodic inspections or be permanently installed for constant monitoring.

GWUT is an excellent screening tool for rapid detection of internal and external wall loss on pipe from 4” to over 48” in diameter. It can be deployed quickly and effectively for periodic inspections or be permanently installed for constant monitoring. Our tomograph unit uses DFA (digitally focused arrays) that can automatically focus the aperture of the acoustic beams to give excellent imaging of internal structures of metals and plastics.

Our tomograph unit uses DFA (digitally focused arrays) that can automatically focus the aperture of the acoustic beams to give excellent imaging of internal structures of metals and plastics. Our PEC service has provided a solution for clients whom require assessment of the remaining wall in carbon steel without access to the surface of the material (liftoff). This volumetric technique is an excellent scanning tool for measuring wall thickness in the following applications:

Our PEC service has provided a solution for clients whom require assessment of the remaining wall in carbon steel without access to the surface of the material (liftoff). This volumetric technique is an excellent scanning tool for measuring wall thickness in the following applications:

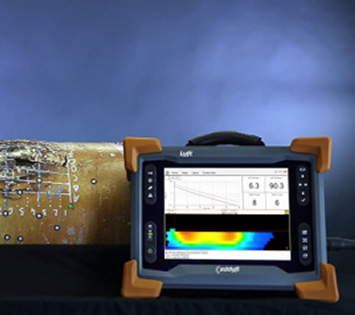

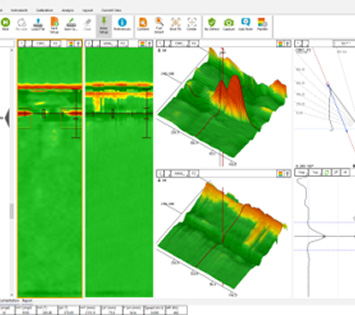

ECA is an advanced eddy current testing technique which uses multiplexing in which multiple coils in a single probe are activated and deactivated in a specific sequence. It offers a wealth of benefits to the quality of data collected and can significantly improve inspection times for surface testing. Our rugged mobile ECA equipment is second to none with a variety of probes for different applications:

ECA is an advanced eddy current testing technique which uses multiplexing in which multiple coils in a single probe are activated and deactivated in a specific sequence. It offers a wealth of benefits to the quality of data collected and can significantly improve inspection times for surface testing. Our rugged mobile ECA equipment is second to none with a variety of probes for different applications:

TISL once again offers heat exchanger tubing inspection using both eddy current and remote field probes but now with the latest technology and equipment

TISL once again offers heat exchanger tubing inspection using both eddy current and remote field probes but now with the latest technology and equipment

The days of harsh chemicals, bulky dark rooms and long processing times are a thing of the past with both CRT and DRT. Since its launch, our CRT system has created massive improvements to our productivity and detection capabilities and DRT affords even more benefits. We now offer the most advanced DRT system in Trinidad that delivers detailed results, instantly, using digital detectors and high-resolution tablets.

The days of harsh chemicals, bulky dark rooms and long processing times are a thing of the past with both CRT and DRT. Since its launch, our CRT system has created massive improvements to our productivity and detection capabilities and DRT affords even more benefits. We now offer the most advanced DRT system in Trinidad that delivers detailed results, instantly, using digital detectors and high-resolution tablets.

TISL offers satellite-based (GPS) tracking devices and software for use on anything from CCUs to mobile equipment. Devices have a rugged, intrinsically safe design and do not require a cell signal allowing it to work in critical zones and offshore. The software supports unique reporting tools for specific events such as geofencing, movement, and historical data on location which are especially useful features for managing assets and invoicing. The Powered Tracker is designed for powered equipment such as generators, welding units, lighting towers, compressors etc. for reporting of engine run times to better schedule maintenance.

TISL offers satellite-based (GPS) tracking devices and software for use on anything from CCUs to mobile equipment. Devices have a rugged, intrinsically safe design and do not require a cell signal allowing it to work in critical zones and offshore. The software supports unique reporting tools for specific events such as geofencing, movement, and historical data on location which are especially useful features for managing assets and invoicing. The Powered Tracker is designed for powered equipment such as generators, welding units, lighting towers, compressors etc. for reporting of engine run times to better schedule maintenance.

Quality assurance is an essential component of any project. TISLoffers assistance in pinpointing the specific requirements your organization must meet to achieve your quality goals as it relates to NDE, quality control and heat treatment. TISL provides a comprehensive range of quality control services utilizing the most modern equipment available today. Experienced technicians, trained to recognize standards such as ASNT, AWS, API, and NACE, have served many local and multi-national companies throughout our region in plant construction and turn- arounds. We can develop detailed procedures to implement and carry out the guidelines of your QC program.

Quality assurance is an essential component of any project. TISLoffers assistance in pinpointing the specific requirements your organization must meet to achieve your quality goals as it relates to NDE, quality control and heat treatment. TISL provides a comprehensive range of quality control services utilizing the most modern equipment available today. Experienced technicians, trained to recognize standards such as ASNT, AWS, API, and NACE, have served many local and multi-national companies throughout our region in plant construction and turn- arounds. We can develop detailed procedures to implement and carry out the guidelines of your QC program.

Our AWS Certified Welding Inspectors develop inspection and welding procedures, as well as qualify welders and welding procedures. Our API510, 570, 653 and CWI inspectors also offer professional NDE and inspection consultancy services for your field engineers and supervisors.

Our AWS Certified Welding Inspectors develop inspection and welding procedures, as well as qualify welders and welding procedures. Our API510, 570, 653 and CWI inspectors also offer professional NDE and inspection consultancy services for your field engineers and supervisors.

TISL offers these highly technical consultancy and inspection services as a core part of our asset integrity management scheme.

TISL offers these highly technical consultancy and inspection services as a core part of our asset integrity management scheme.

TISL’s certified coating inspectors are all trained at our training facility in Marabella by highly qualified and experienced lecturers directly from NACE International. We are equipped with the expertise in carrying out and providing guidance on any coating project to ensure QA/QC requirements are met and adhered to.

TISL’s certified coating inspectors are all trained at our training facility in Marabella by highly qualified and experienced lecturers directly from NACE International. We are equipped with the expertise in carrying out and providing guidance on any coating project to ensure QA/QC requirements are met and adhered to.